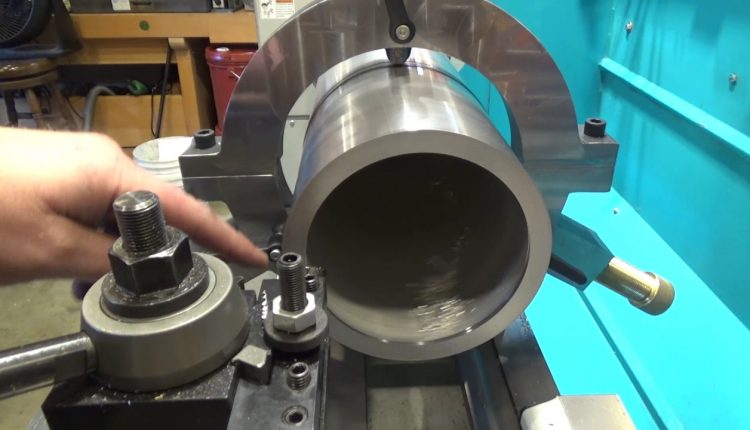

Turning a 7" Diameter Aluminum Dive Tank into a Bell

This project was merely an experiment to try turning a large diameter object on my lathe using my newly made steadyrest.

Mistakes were made….

Please Note: I am a beginning machinist and I do not pretend to know everything. Please always operate machinery in a safe manner and if you don’t know, find a reliable source. DO NOT COPY ME. I make a lot of mistakes. I provide these videos for entertainment only.

Rating: 4.35

Great idea. I took some small o2 tanks and made oil containers. When machining cylinders put a piece of rubber hose around the inside. That helps on the loud singing of the cylinder(don't know the technical term). I believe I seen that on abom79. Very nice job.

I’m kind of stupid with the technical aspects of making a bell with good harmonies, but just fascinated with the whole video!!! I know I’d just be asking a lot of questions and aggravating you, but would just love to sit in your shop and watch one of these projects come to life!!! Thanks again and looking forward to another great video!!!

Art

Maybe there is a correlation between all the vibration you removed during turning and the lack of same at the end. That bell sounds like a dying camel, no offence. Great video though 🙂

second time has to be a charm maybe this time the phone won't ring

You would have been wiser to grab on the OD for the 1st operation…

As pointed out by several people, the plug in the tube affects the tone. I believe if you remove the screwed in plug you will have a deep toned bell. The tone of the tube is directly related to diameter, length, thickness, and material as well as whether the tube is open or closed. A cast bell is not necessarily perfect circles. In physics there are formulas for bells and chimes. There are YT videos on making wind chimes. Your approach was interesting. To make the slots another approach is to use a slitting saw instead of the end mill.

Scuba an other pressure tanks are hydro tested each 5 years for safety. If they fail they are drilled if they didn't split. You are correct that 2100 or 2700 psi can be a bomb.

Should have annealed it at the first sign of internal stress. Temps would have been low enough to accomplish in your oven.

Would a heat cycle have released the tension? It was work hardened right?

Longer the 'bell' is the lower the tone. Short is high. Make a ring of 4' down to 1' 1" ID tubing. Those on porches are high pitch short. I have a long one out with the tractor in the shed. It has a flapper that catches wind and a line up to the hanger of the ring a ringer . Good first start!

Couldn't you have turned down one section to round enough for your steady rest to run on the work on the rest of it?

I think working with metal is just one of the coolest things ever. I cannot tell you how many times I've utilized a good machinist for projects. Long story short if I could hit the rewind button I would have become a machinist. I actually took a class at a local community college. Sadly the program disappeared. Nothing like a great lathe & milling machine. I live in Iowa and concur with a few others. In the summer the humidity usually matches the temperature & in the winter your face can get chapped due to the humidity combined with the cold. Take care & Happy New Years to you from Iowa.

"Definatlety"?

what do you expect? its a container not a bearing.

Sounds like a Japanese temple bell 😀

Nice project and fun to watch. Lots of complexity built in…internal stress, size of the material, out of roundness, work holding challenges, no applicable reference from machinery handbook , and of course there is the physics of acoustics. Lots wrapped into one package. Nice job!

mightl ve been better to start with cutting some grooves on the outside for the bearings of the steady rest to ride in and then making the inside edge mostly round and straight (should've create less tensions in the material and keep it more round during its build )

then do the finish on the outside last , once its done it doesnt matter too mush that it looses its shape , it might keep the total wall thickness just that little more compared to keep skimming the outside to clean it up every time you used the steady rest

about cutting the outside grooves and the part vibrating

there welding clamps available that buts two pieces of sheetmetal in the same plane for welding

https://www.google.com/search?q=but+welding+panel+clamps&newwindow=1&source=lnms&tbm=isch&sa=X&ved=0ahUKEwj63o-dgMHfAhXQZVAKHR4XC4oQ_AUIDigB&biw=1090&bih=510#imgdii=ky7MIKM8dZOIoM:&imgrc=VLBrgSRWl16NOM: should work on the taps too

think the resonance is mostly caused by the tension in the metal (think drum skins that sound / resonate better when there tight ), you took the internal tension out when you cut the grooves in

making the top a screw in acts like a dampener too , think if you take that out and hang it from a wire it might resonate a little better or create more tones

gonnah be pretty loud , unless youre using a verry small hammer/ ball i think neighbours as far as three doors down are going to complain if you hang it out in the yard

saw won being filled valve failed knocked over trash barrel full of water to keep kool during fill went through trash barrel then wall 1/4 inch plywood & ended up about 150ft from where it started . 3000psi baby !

I never knew those tanks were that thick. Makes sense.

Good video. Enjoyed that.

Old steel tanks have a better sound

Look up the word bell. Bell shape. You are making a bell aren't you. But keep playing with the lathe. I think that is your purpose

would you like to know how to get the best sound?………………………………………………………………….JS*

I make wind chimes. The secret to a nice tone is two fold. The top needs to resonate in the harmonic or it needs to be neutral. I would have left the original top on the tank and then hung it with and insulated wire, such as plastic coated stainless fishing line. Try it without the threaded top. The second item that affects the tone is the length of the side. Look on Google for wind chimes and you will see the length of pipe needed for "C" or "A" or ???. Pick a multiple of that number so cut that number in half or 2x or 4x the length. You will find that the best tone will be when you find the length you want and it is a harmonic of the diameter of the tank. Diameter is 8.75" and the length is 17.5" (2x) or 26.25" (3x). enjoyed watching.

yes, also to normalize the aluminum and soften it.

Heat cycle the tank to relive the stress, than the ring will sound sweeter.

I get that this was an excuse to turn a cylinder but as a blacksmith, it is common for us to turn tanks into bells, you STARTED with a bell and it went down hill from there LOL! If you had made a plug/hook to fit in the threaded neck… as a bell, it would have been done 😛 I do get the whole excuse for turning though 😀

I'd really like a good view of lathe rest you are using here coz' I need / want something just like it.

Use a hard wood ball for a donger. I will soften the sharp sounding blow.

bells don't have flat tops. when you parted off the inlet you messed up the resonance. I just don't understand why you did what you did. waste of good material.

I didn't think it was a waste of time. Any time you learn something it is an investment in you! Besides, it gave you a great opportunity to use the rest you made. "what a waste of time" – I really find those sort of comments ridiculous. A waste of time was the comment. Yeah why didn't you just go out and buy a bell!!!!! I think he missed the point! Thanks for sharing. Enjoyed the content. Cheers mate.

i bet if you had just left it hollow and didnt cut any slots in it, it would have sounded better.

try a heat treat make it harder

great video, release the tension by heating the metal, then letting cool slowly, others probably have the best temp range for aluminum, I'm not a metallurgist, but learned a lot from others.

If you ever do this again, leave the top on. You should get a more pleasing tone. I'm pretty sure that adding the threaded top was a bad idea. Try removing it, drill three holes around the top, hang it from that & see if the tone improves.

Also, there is this amazing little tuner called a Snark, they're about 15 or 20 bucks. The one I have says "guitar & bass tuner" on it but it's worked for anything I've tried it on including bells or chimes. They even have pitch calibration in case you want to tune to 432 vs 440 or something. These are the most amazing little tuners, especially for the price, hands down.

When you parted the head off it let the tank relax. Pipe does the same thing when you split it down the side.

There are formulas for finding the tone of a rod / bar / cylinder .

Jesus H Christ you don't grab fucking shavings that are turning on a lathe I don't care if they're aluminum or not I just just just two days ago almost lost two fingers because a long curl was hanging down in front of my apron and I when I was turning the longitudinal wheel I didn't notice it wrapped around two fingers and almost took them off I'm totally laid up I can't even move them. It's just by pure luck that my fingers are still attached and you're intentionally sticking your hand in there grabbing them please stop

50% humidity is like an arid desert that is not how you midity LOL

I have several scuba tanks in my basement but doubt I'll chop them up just yet lol loved your video very interesting project and was cool to see a dive tank chopped up.

Awesome project, should look into AC for the shop, I just bought a mini split ac system for myn a couple weeks ago and its been great, and it was pretty affordable

I had no idea how thick those tanks were….

You should have turned a flat spot for your steady rest so you could control the movement a little bit better

Good work continued